Boston Dynamics Prices Atlas Robot for Factory Floor Competition

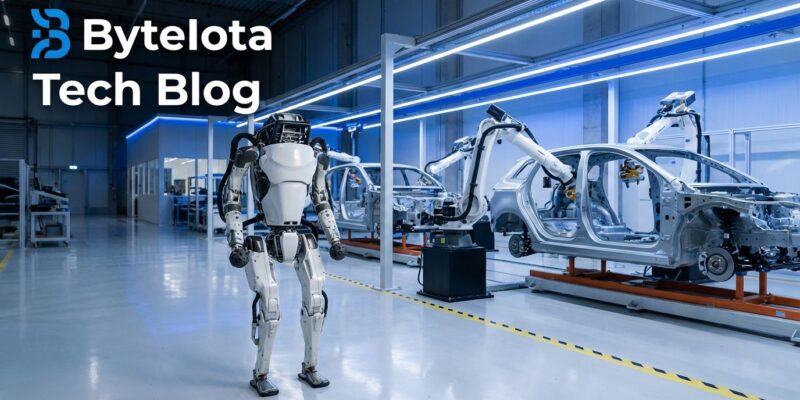

Boston Dynamics has announced pricing for its production-ready Atlas humanoid robot, signaling a major shift toward commercial viability in manufacturing. The move challenges traditional labor economics in industrial automation.

The Humanoid Reckoning Arrives

The race to replace human factory workers just entered a new phase. Boston Dynamics has unveiled pricing for its production-ready Atlas robot, marking the first time a major humanoid manufacturer has publicly positioned its technology as a direct economic alternative to human labor in manufacturing environments. This isn't theoretical anymore—it's a commercial proposition.

The timing matters. While competitors scramble to prove technical feasibility, Boston Dynamics is already planning production scale-up, with manufacturing operations set to begin in 2026. The company's redesigned electric version represents a fundamental shift from research platform to industrial tool.

What Changed: From Demo to Deployment

Boston Dynamics' Atlas has always been impressive—but impressive doesn't pay the bills. The new production model addresses the gap between viral videos and factory floor reality:

- Autonomy improvements: The latest iteration demonstrates genuine autonomy in real-world tasks, not just choreographed demonstrations

- Cost structure: Pricing now reflects manufacturing at scale, not one-off engineering projects

- Task versatility: The robot is being trained to handle diverse factory operations, from parts handling to assembly sequences

The electric redesign is crucial here. Previous hydraulic versions were powerful but expensive to maintain and operate. The shift to electric actuation reduces operational costs and aligns with manufacturing facilities' existing infrastructure.

The Economic Calculus

Here's where the story gets interesting for manufacturers: the total cost of ownership now competes with human wages in high-cost labor markets. Industry analysts are already flagging humanoid robotics stocks as potential growth drivers, suggesting institutional investors see this as a genuine inflection point.

The math is straightforward:

- Factory workers in developed economies: $50,000-$80,000+ annually (with benefits)

- Atlas unit cost + maintenance + power: Increasingly competitive on a per-shift basis

- Uptime and consistency: Robots don't call in sick or require training

Boston Dynamics isn't claiming Atlas will replace all factory workers—that's both technically and politically unrealistic. But for specific, repetitive tasks in controlled environments, the economic argument is becoming unavoidable.

What's at Stake

This announcement carries weight beyond Boston Dynamics' balance sheet. The broader robotics sector is watching closely, as successful commercialization of humanoid robots could unlock entirely new categories of industrial automation.

The implications ripple outward:

- Manufacturing economics: Facilities will need to recalculate labor strategies

- Workforce planning: Companies must decide whether to compete on cost or shift to higher-value work

- Technology adoption: Early movers gain competitive advantage; laggards face margin pressure

The Realism Check

Boston Dynamics' pricing announcement is significant, but execution remains the test. Robots in controlled demos perform differently than robots in real factories with variable conditions, equipment failures, and edge cases. The company has made impressive strides, but scaling production while maintaining reliability is a different challenge entirely.

What's clear: the era of humanoid robots as curiosities has ended. Atlas now competes in the same economic arena as human labor. Whether manufacturers embrace that opportunity—or resist it—will define the next decade of industrial automation.

The question isn't whether humanoid robots will eventually compete with factory workers. The question is how quickly, and at what scale.