Revolutionizing Cold Chain Logistics with AI

US Cold Storage transforms logistics with AI, automating scheduling and enhancing efficiency across 38 facilities, setting a new standard in cold chain logistics.

Revolutionizing Cold Chain Logistics with AI

United States Cold Storage (US Cold Storage), a leader in temperature-controlled logistics, has embraced a transformative approach to supply chain automation. By deploying FourKites’ AI-powered digital agent, Alan, US Cold Storage is automating appointment scheduling across its 38 facilities nationwide. This shift from manual coordination to AI-driven efficiency is not just a technical upgrade but a significant transformation in cold chain logistics.

The Cold Chain Challenge

Cold chain logistics involves the transportation and storage of temperature-sensitive goods. This high-stakes industry faces challenges such as product spoilage and compliance failures due to delays or errors. Traditionally, scheduling shipments has been labor-intensive, involving coordination across multiple time zones and prone to human error.

US Cold Storage recognized the potential of automation to enhance efficiency, reduce costs, and improve customer satisfaction. Partnering with FourKites, they piloted Alan, a digital worker capable of autonomously handling complex scheduling tasks.

Key Features of the AI Solution

How Alan Works

Alan is an advanced AI agent that understands natural language, interprets complex scheduling requirements, and interacts directly with customers and carriers to book appointments without human intervention. During the eight-week pilot, Alan processed over 600 shipments, achieving an 87% success rate in booking appointments and 96% accuracy in securing requested delivery dates. Operating 24/7, Alan can handle more than 150 appointments simultaneously.

Immediate Benefits

- Productivity Gains: The pilot saved an estimated 36–40 hours of staff time, allowing employees to focus on strategic tasks.

- Accuracy and Speed: Automation reduces errors and speeds up scheduling, improving supply chain reliability.

- Scalability: Alan’s ability to handle multiple appointments means operations can scale without increasing staff.

- Customer Experience: Faster, more accurate scheduling enhances service levels and responsiveness.

Integration with Existing Systems

Alan integrates seamlessly with US Cold Storage’s existing platforms, ensuring continuity and minimizing disruption. The AI agent uses historical data, real-time traffic conditions, and warehouse capacity to optimize scheduling decisions.

Industry Impact and Broader Trends

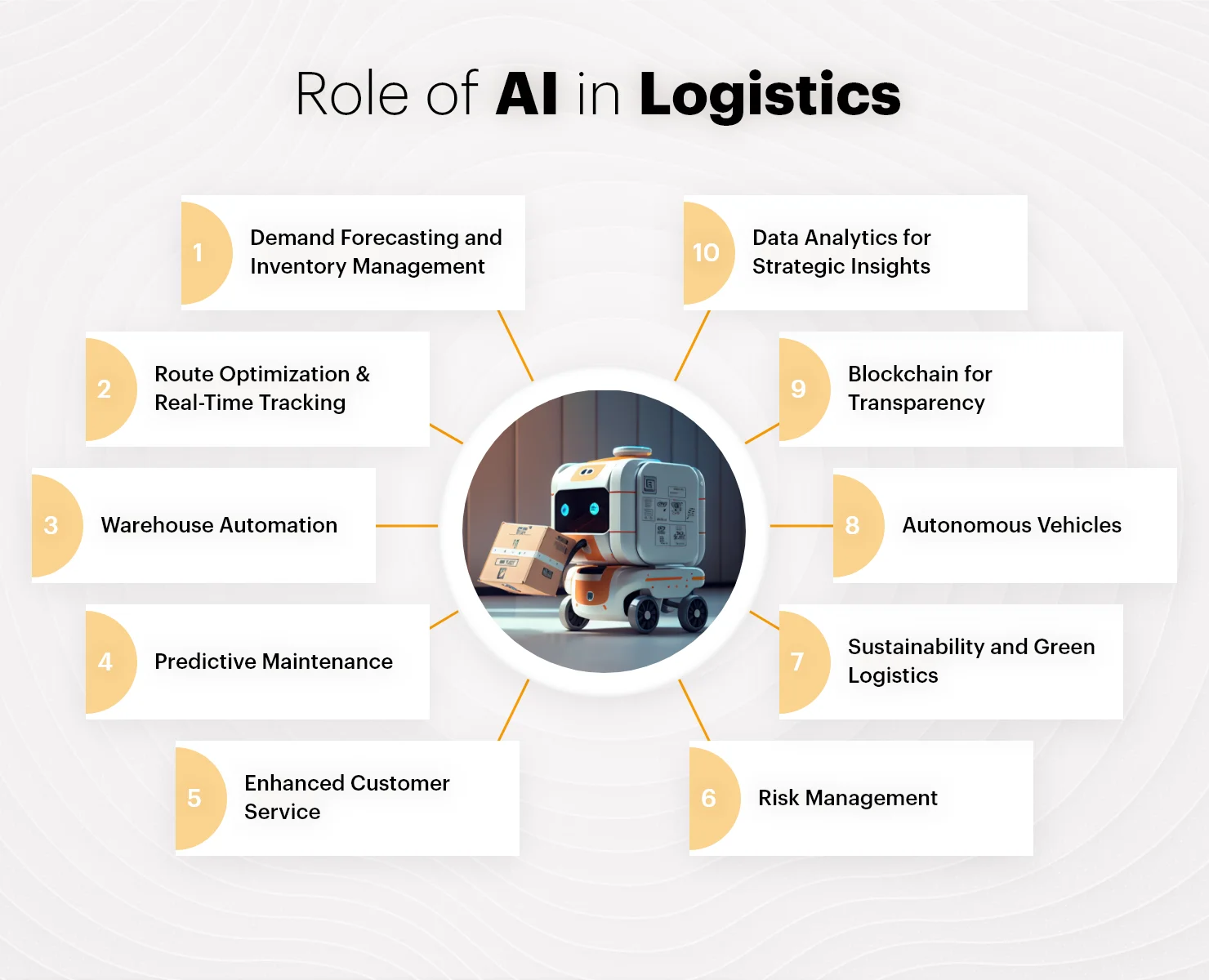

The Rise of AI in Logistics

US Cold Storage’s adoption of Alan reflects a broader industry shift toward intelligent automation. Companies are deploying AI-powered robotics and algorithms to streamline operations and improve accuracy. For example, Lineage Logistics uses AI-powered computer vision to automate pallet receiving.

Market Adoption and Investment

The global AI in warehousing market is projected to reach $45.12 billion by 2030. Nearly 40% of cold storage companies have implemented AI-based inventory systems to optimize power usage and shelf-life management.

Competitive Landscape

Companies that fail to embrace these technologies risk falling behind. The integration of IoT sensors, real-time monitoring, and blockchain for traceability is becoming standard, driven by the growth of temperature-sensitive pharmaceuticals and the push for green logistics.

Context and Implications

Workforce Transformation

AI agents like Alan redefine jobs rather than eliminate them. Staff are freed from repetitive tasks to focus on customer service and strategic initiatives, requiring upskilling and a culture of innovation.

Sustainability and Compliance

Automation supports sustainability by optimizing energy use and reducing waste. Enhanced data visibility helps maintain compliance with food safety and pharmaceutical regulations.

Future Outlook

The success of US Cold Storage’s pilot suggests AI-driven automation will soon become the norm. As technology matures, further integration with robotics, IoT, and blockchain will create fully autonomous warehouses, driving down costs and improving service levels.

Conclusion

US Cold Storage’s AI leap is a pivotal moment for logistics. By automating scheduling with FourKites’ Alan, the company has shown that AI can deliver immediate benefits, reducing manual effort and enhancing customer satisfaction. This initiative is part of a broader transformation, as cold chain logistics evolves into a data-driven, intelligent network. Companies that embrace these technologies early will thrive in an increasingly complex market. The future of logistics is autonomous, adaptive, and AI-powered.